In the remote Gobi Desert of Ningxia, China, DEEP Robotics has completed an autonomous inspection project at an unmanned wind power substation — achieving a remarkable 96.5% recognition accuracy across over 200 inspection missions. The project, running from August 2024 to February 2025, demonstrates how AI-driven quadruped robots can transform maintenance operations in some of the world’s most challenging environments.

Once, maintenance teams had to travel more than ten kilometers along gravel roads after leaving the main highway just to reach the wind farm — often in scorching heat, high winds, or freezing cold. Today, those same operators receive detailed inspection reports from the DEEP Robotics quadruped robots directly in their offices — in real time, without ever setting foot in the desert.

Autonomous Patrols in the Harshest Environments

This breakthrough project was jointly developed by DEEP Robotics, Goldwind Smart Energy, and the China Three Gorges Corporation. Located deep within the unmanned Gobi wind power zone, the substation sits 10 kilometers away from the nearest inhabited area, covering an inspection area of 1 square kilometer.

The robots’ patrol targets include main transformers, bushings, disconnect switches, lightning arresters, and switching indicators — all key assets that determine the stability of wind energy output.

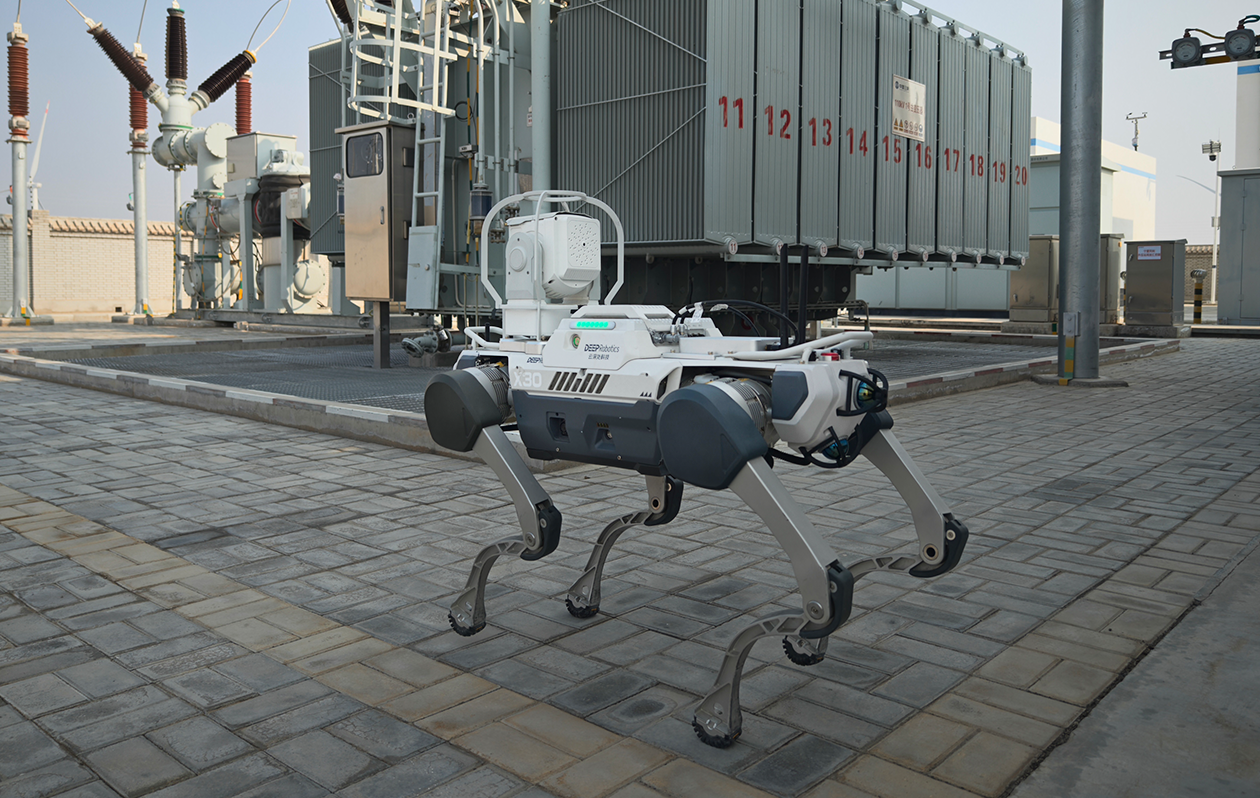

To ensure reliable coverage, DEEP Robotics deployed its X30 quadruped robot in collaboration with autonomous drones, performing two full inspection rounds per day, each lasting about 80 minutes. The system continuously uploads data to a cloud-based platform, automatically generating comprehensive inspection reports with both visual and thermal analytics.

Exceptional Durability in Extreme Conditions

The X30 robot proved its resilience in the Gobi’s punishing environment — enduring high temperatures, abrasive sandstorms, and light to moderate rainfall while maintaining stable, autonomous operation.

Even under adverse weather, the robot completed its AI-powered recognition tasks with precision, reading instrument dials, analyzing thermal signatures, and instantly flagging anomalies. This proactive detection helps prevent costly equipment failures and ensures continuous energy delivery from the wind farm.

Since deployment, the X30 has operated at industrial-grade stability, maintaining consistent uptime and accuracy under all conditions. Leveraging DEEP Robotics’ advanced AI perception system and embodied intelligence control algorithms, the inspection solution achieves true 24/7 unmanned operation — replacing manual patrols in extreme environments and dramatically reducing human risk, travel time, and operational costs.

Precision AI Recognition with 96.5% Accuracy

Among the 349 inspection checkpoints, 40 critical points required precise AI-based recognition — such as gauge readings, temperature measurements, and switch positions. DEEP Robotics’ intelligent recognition algorithms achieved 96.5% accuracy, ensuring every reading was logged and transmitted reliably to the monitoring platform.

The result is a fully automated inspection workflow where human operators can focus on decision-making rather than data collection. With continuous, verifiable insights, maintenance teams gain a real-time overview of substation health and can intervene proactively before faults occur.

AI-Powered Robotics for Clean Energy Infrastructure

As one of the flagship projects under DEEP Robotics’ AI+ Initiative, the success of the X30 quadruped robot in the Ningxia Gobi wind farm underscores the company’s leadership in AI-powered autonomous inspection. It also demonstrates a new model for intelligent management of clean energy facilities — combining robotics, AI, and cloud data analytics.

Looking ahead, DEEP Robotics will continue to advance its technology stack in embodied intelligence, expanding applications across energy, utilities, and infrastructure inspection. By delivering reliable, autonomous systems for extreme environments, DEEP Robotics is helping industries transition toward safer, smarter, and fully automated operations — driving the global shift to sustainable, intelligent maintenance.