Within the dense web of cables and towering equipment of modern substations, maintenance and inspection remain among the most demanding operations in the power industry. Traditional manual patrols expose workers to harsh weather, complex terrain, and significant safety risks — while human accuracy and efficiency can no longer meet the precision and reliability demanded by digital power grids.

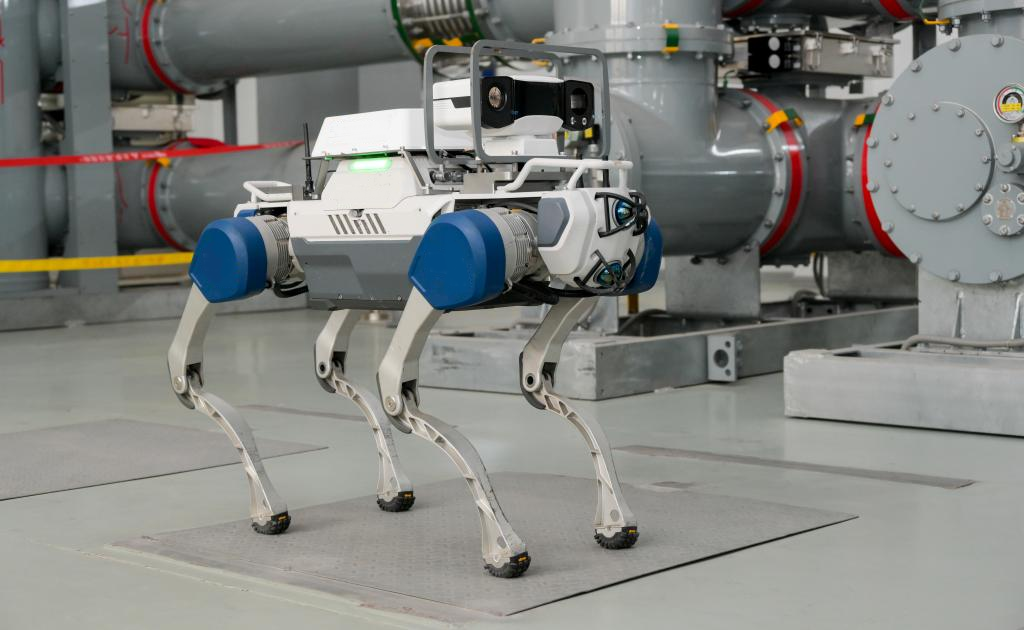

To overcome these operational challenges, DEEP Robotics collaborated with a leading Zhejiang-based power utility to deploy its AI-driven quadruped inspection solution, led by the Jueying X30. This deployment marked a key milestone in applying embodied intelligence to transform power operation and maintenance, achieving measurable improvements in both safety and performance.

1. Smart Innovation: Tackling Complex Substation Environments

In real-world field operations, DEEP Robotics’ quadruped robots demonstrated exceptional environmental adaptability.

The Deep Robotics X30, built on a high-mobility legged platform, replicates human patrol routes with remarkable agility. Capable of navigating grass, steps, slopes, and narrow aisles with ease, it covers inspection zones that are either unsafe or unreachable for humans.

Equipped with a suite of high-precision sensors — including an HD visible-light camera, infrared thermal imager, and LiDAR — the X30 performs multi-modal inspections simultaneously, identifying equipment anomalies, reading gauges, and measuring temperature variations in real time.

Powered by reinforcement-learning-based navigation algorithms, the robot autonomously avoids obstacles and plans routes dynamically, even in densely packed equipment areas. With an IP67-rated industrial chassis, it operates reliably in rain, snow, and dust, maintaining continuous inspection for hours on a single charge.

Its auto-docking and task resumption system ensures uninterrupted operation, completing tasks autonomously even after battery swaps or charging cycles.

This deep integration of high-mobility robotics and AI perception effectively resolves long-standing challenges in terrain adaptation, data accuracy, and continuous automated inspection — redefining how substations achieve operational resilience.

2. Proven Results: Accuracy and Efficiency Reimagined

Field data shows outstanding performance improvements following deployment.

DEEP Robotics’ quadruped robots achieved a 98% overall inspection accuracy, including:

-

≥98% accuracy in instrument reading recognition

-

99% accuracy in temperature measurement and equipment status detection

-

Zero missed defect alerts, with combined algorithm performance reaching 99%

These precision metrics significantly enhance the reliability of substation monitoring and predictive maintenance.

In terms of operational efficiency, the X30 completes a full-station inspection in under 35 minutes — compared with over an hour required by human patrols — covering more than 90 pieces of equipment per cycle.

Automated data collection and report generation have reduced manual workload and turnaround time by over 50%, while operational costs decreased by approximately 70%. The system’s low maintenance requirements and minimal infrastructure upgrades deliver exceptional lifecycle cost performance, making it a model solution for intelligent power operations.

3. Expanding Horizons: A Model for Smart Grid Transformation

The success of DEEP Robotics’ quadruped robot in substation applications provides a valuable reference for the intelligent transformation of the power sector.

Its field-proven performance demonstrates that effective automation must align with real operational demands — combining robust mobility, multi-sensor fusion, and modular system integration.

The inspection system supports seamless interoperability with existing SCADA and automation systems, avoiding data silos while enabling coordinated operation among different inspection devices and human operators.

“Our robotic system can model a substation and plan routes within one to two days, with a 500-point configuration completed in just two to four weeks,” said a DEEP Robotics engineer. “That speed of deployment sets a new benchmark for intelligent O&M solutions.”

With successful deployments across substations of different voltage levels, DEEP Robotics’ quadruped platforms have proven capable of handling complex terrains, dense equipment layouts, and extreme weather — unlocking new potential for power infrastructure modernization.

4. Toward a Smarter, Safer, Greener Future

By integrating AI, robotics, and digital management, DEEP Robotics’ “human-robot-system” collaboration model creates a new framework for the next generation of intelligent operations.

Its solutions combine precision sensing, real-time decision-making, and autonomous mobility to minimize human exposure to risk while maximizing system uptime and energy efficiency.

Looking forward, DEEP Robotics will continue advancing its embodied intelligence technologies, driving autonomous inspection, fine-grained maintenance, and cross-system collaboration across the energy sector.

With every deployment, the company moves closer to realizing a safer, more efficient, and sustainable future for intelligent infrastructure worldwide.