Key Takeaways: The 2025 Autonomy Trinity

- The “Brain” Shift: We have moved from “coding walking” to “teaching walking” using Sim-to-Real Reinforcement Learning (RL) in platforms like NVIDIA Isaac Lab.

- The Hardware Hybrid: Wheel-leg robots (like the Deep Robotics Lynx M20) are solving the battery bottleneck, offering up to 83% greater energy efficiency on flat ground.

- The Democratization: Research-grade quadrupeds capable of running VLA (Vision-Language-Action) models have dropped from $75,000 to the $2,000–$20,000 range.

The era of “keyframe animation” for robots is officially over. As of late 2025, the robotics industry has abandoned the model of engineers hand-coding every footstep. Instead, we have entered the age of Physical AI.

Just as Large Language Models (LLMs) like ChatGPT learned to predict text by reading the internet, Physical AI robots are learning to navigate the physical world by experiencing millions of years of trial and error in massive parallel simulations. This shift is not just academic; it is transforming industrial asset management, lowering barriers for STEM education, and creating a “ChatGPT moment” for embodied intelligence.

Definition: Physical AI

Physical AI refers to robotic systems that develop motor skills (locomotion, manipulation) and semantic understanding through Deep Reinforcement Learning (RL) and World Foundation Models, rather than rigid if/then programming. These robots possess proprioceptive sensing—an innate awareness of their body mechanics in relation to unstructured environments.

1. Beyond Pre-Programmed Paths: The “Sim-to-Real” Revolution

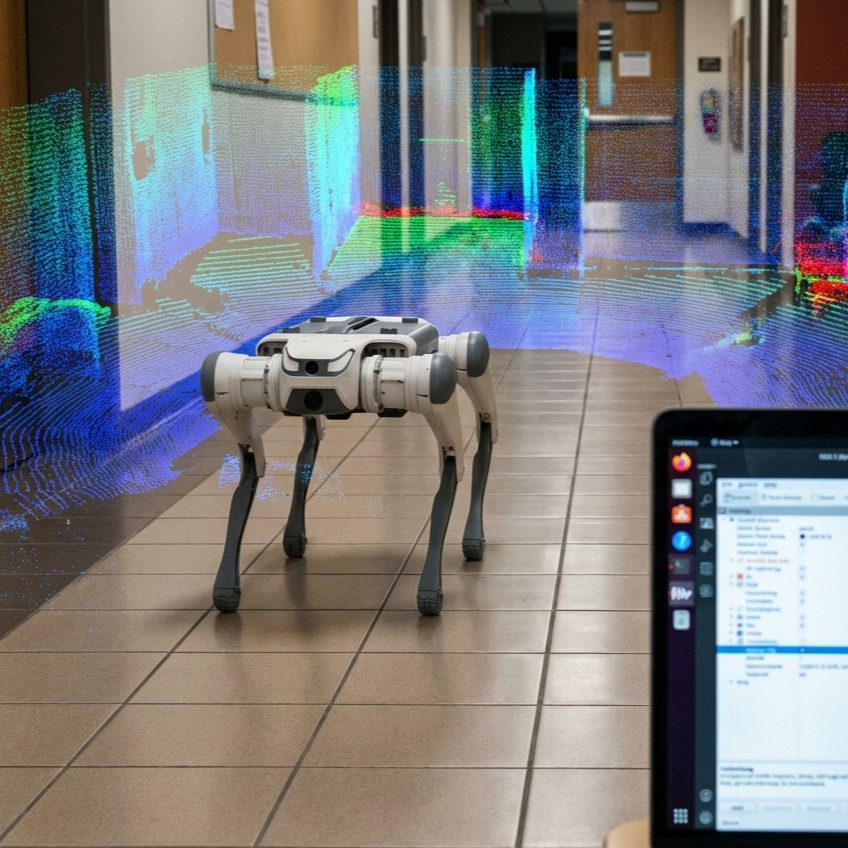

For decades, a robot dog walking on gravel required complex mathematical modeling of friction coefficients. In 2025, that approach is obsolete. Today’s quadrupeds, such as the Unitree Go2 or the industrial-grade Deep Robotics X30, utilize policies trained in environments like NVIDIA Isaac Lab.

Through a technique called Domain Randomization, developers simulate a “multiverse” where gravity, floor friction, and payload weight change randomly every second. The AI is forced to learn a general locomotion policy that adapts to any reality.

The “10,000 Years in a Day” Benchmark

Modern training pipelines allow robots to experience 10,000 years of walking simulation in a single day of real-time computing. This results in Zero-shot generalization, meaning a robot can successfully navigate a muddy construction site on its first try, even if it was only ever trained in a digital void.

| Feature | Traditional Robotics (Pre-2023) | Physical AI (2025 Standard) |

|---|---|---|

| Control Method | Model-Based Control (PID, ZMP) | End-to-End Reinforcement Learning |

| Adaptability | Fails on unmapped obstacles | Robust to “messy” unstructured terrain |

| Recovery | Requires manual reset after fall | Self-righting and continued operation |

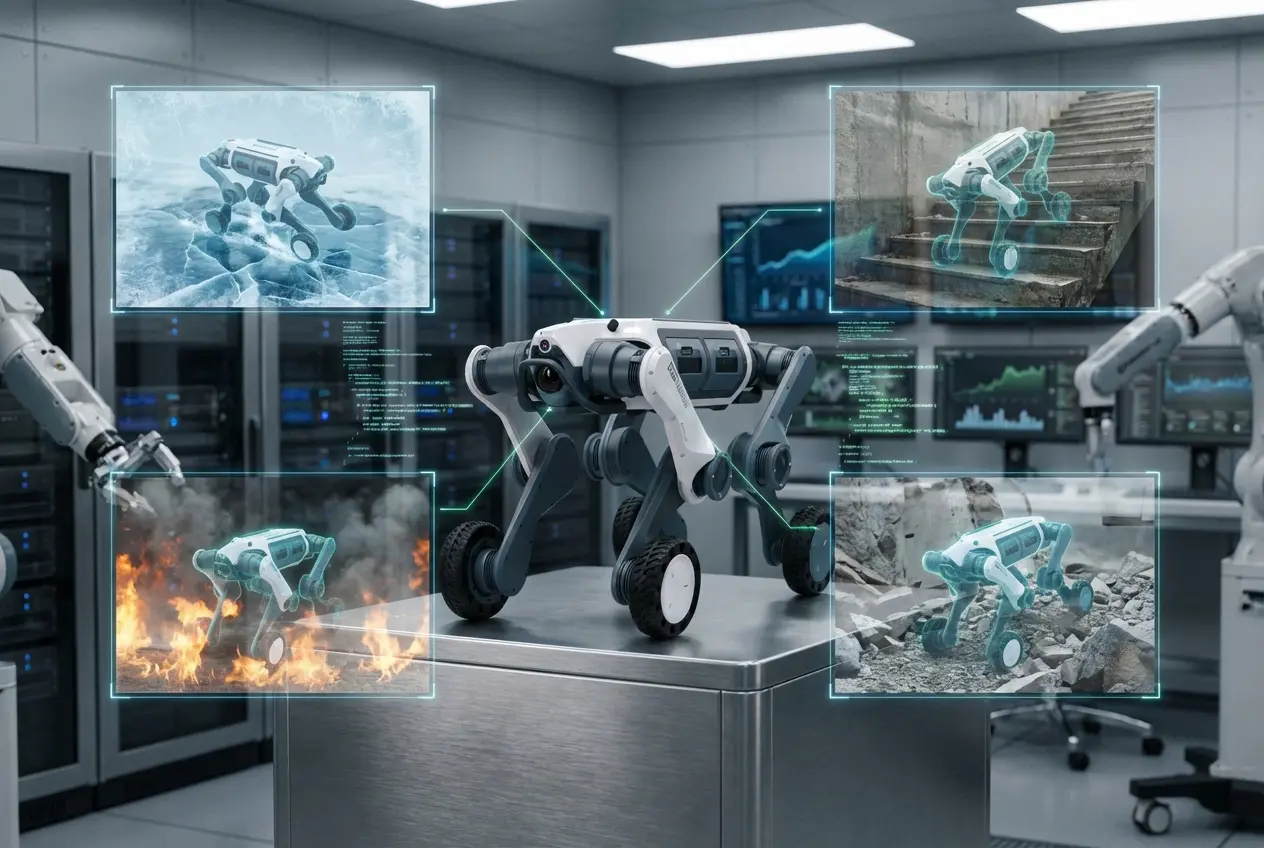

2. The Rise of the “Wheel-Leg” Hybrid

One of the most significant hardware trends of 2025 is the convergence of locomotion modes. Industrial users historically faced a dilemma: wheels are efficient but cannot climb stairs; legs are agile but drain batteries quickly. The solution is the Wheel-Leg Hybrid.

Robots like the Deep Robotics Lynx M20 and the Swiss-Mile (RIVR) platforms have disrupted the market by combining the best of both worlds. According to recent industry benchmarks, these hybrids offer up to 83% more energy efficiency on flat surfaces compared to pure walkers.

Deep Robotics Lynx M20: A Case Study in Hybrid Agility

The Lynx M20 exemplifies this shift. It utilizes wheels for high-speed transit on warehouse floors (reaching speeds up to 5m/s) but locks its wheels to step over obstacles up to 25cm high or climb 45-degree slopes. This solves the “last 100 yards” problem in logistics where a robot must drive a kilometer efficiently, then climb a loading dock.

- Speed & Range: The Lynx M20 achieves a 4-hour endurance range (unloaded) by driving rather than stomping.

- Payload: With a 15kg payload capacity, it serves as a robust courier for heavy sensors or logistics packages.

- Terrain: It can execute U-turns in narrow 50cm passages, a critical metric for confined industrial spaces.

3. Industrial ROI: From “Cool Gadget” to Semantic Asset

For industrial sectors like Oil & Gas, Energy, and Mining, the novelty of a robot dog has worn off. The focus in 2025 is purely on Return on Investment (ROI) through Semantic Inspection.

Early adopters like Shell and Chevron are reporting a 30% reduction in inspection time. The robot is no longer just a camera carrier; it is an intelligent node in the facility’s Digital Twin. It doesn’t just record video; it reads thermal gauges, detects gas leaks, and updates the central database automatically.

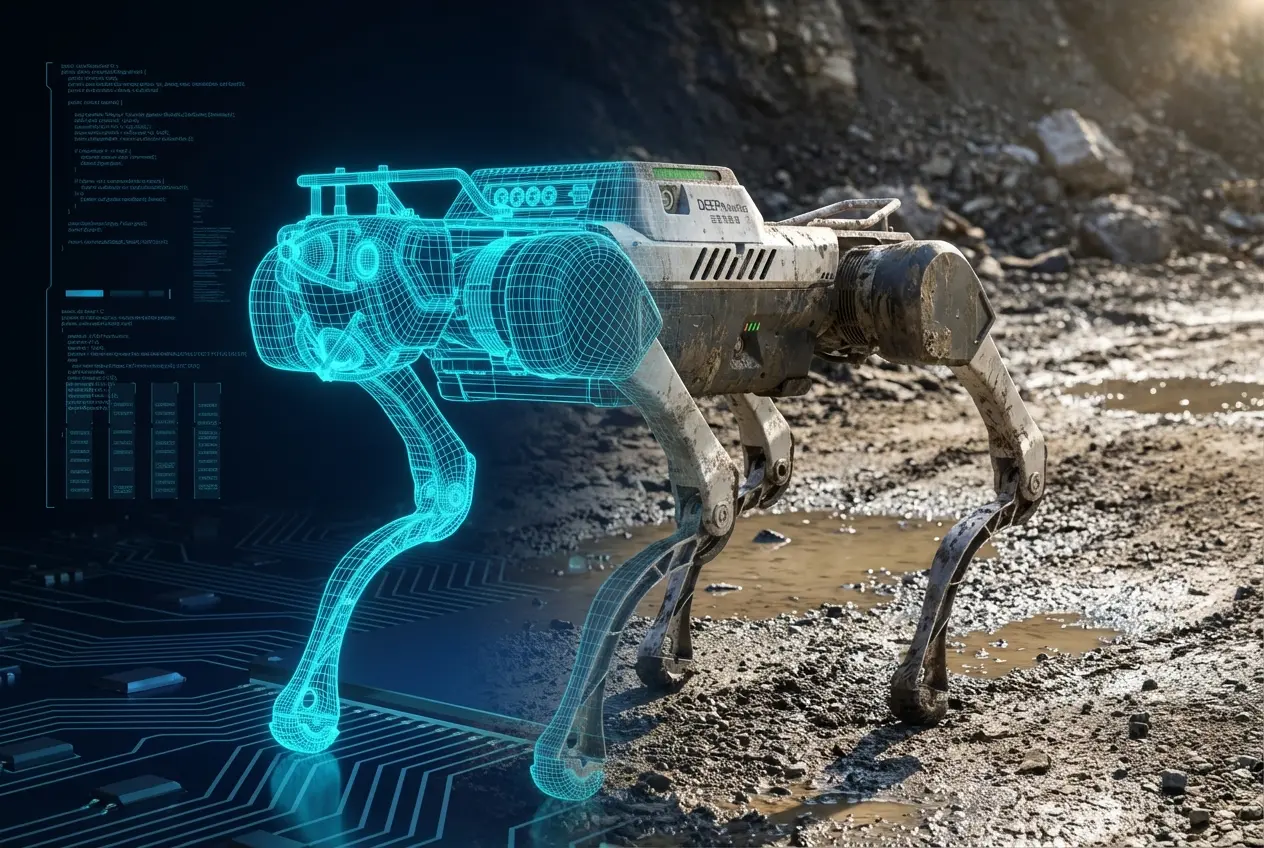

The Deep Robotics X30: Built for the Extreme

To achieve this ROI, hardware must survive environments that kill consumer electronics. The Deep Robotics X30 flagship is engineered specifically for this “dirty work.”

- Fusion Perception: Unlike camera-only robots that fail in the dark, the X30 uses LiDAR and fusion perception to operate in complete darkness or blinding glare.

- Extreme Temperature Range: It is certified to operate from -20°C to 55°C, making it viable for Arctic pipelines or Middle Eastern solar farms.

- IP67 Protection: It is fully waterproof and dustproof, allowing for autonomous missions during rainstorms where human inspection would be dangerous.

4. The Democratization: Education and the “Prosumer” Market

Perhaps the most exciting shift is the plummeting cost of entry. Three years ago, running advanced RL policies required hardware costing upwards of $75,000 (e.g., Boston Dynamics Spot). In 2025, the Unitree Go2 Edu and Deep Robotics Lite 3 have brought this capability down to the $2,000 – $20,000 range.

The “ChatGPT Moment” for Physical Machines

This price drop allows high schools and small university labs to access Embodied AI. Students are now programming robots using Python and VLA (Vision-Language-Action) models, essentially giving the robot a “LLM brain” that can understand natural language commands like “Find the red ball and push it to the door.”

Deep Robotics Lite 3 Specs for Researchers:

- Torque Density: “Torque Revolutionized” motors allow for high-difficulty maneuvers like handstands.

- Open Architecture: Supports extensive secondary development via SDK/API, allowing students to inject their own AI code.

- Payload: A 7.5kg walking load capacity allows for the mounting of custom sensors or robotic arms for manipulation research.

5. Step-by-Step Strategy: Implementing Physical AI

Whether you are a researcher or a facility manager, adopting this technology requires a strategic approach.

- Define the Domain: Do you need endurance (Wheel-Leg/Lynx) or extreme terrain capability (Legged/X30)?

- Select the Simulation Environment: For developers, start with NVIDIA Isaac Lab or Gazebo to train your RL policies before buying hardware.

- Integrate the Digital Twin: For industry, ensure the robot’s data output formats (ROS2, Point Clouds) integrate with your existing asset management software.

- Deploy Semantic Payloads: Equip the robot with edge-compute modules (like NVIDIA Jetson Thor) to process data locally, reducing bandwidth usage.

6. Frequently Asked Questions (FAQ)

What is the difference between “Traditional Robotics” and “Physical AI”?

Traditional robots follow rigid, hand-coded scripts (if/then logic) and struggle when the environment changes. Physical AI robots learn skills like balancing and navigation through trial-and-error in massive simulations (Reinforcement Learning), allowing them to adapt dynamically to unpredictable environments like debris-filled disaster zones.

Why are wheel-leg hybrid robots becoming popular in 2025?

Wheel-leg hybrids, such as the Deep Robotics Lynx M20, offer the “best of both worlds.” They provide the speed (up to 5m/s) and battery efficiency of wheels on flat concrete—crucial for large warehouses—while retaining the stair-climbing agility of legs to overcome obstacles, solving the range anxiety that plagued purely legged robots.

Are robot dogs worth the investment for small industrial sites?

Yes. With costs for capable units like the Lite 3 or Unitree Go2 dropping below $3,000, the ROI for automated thermal inspections or security patrols can now be realized in under 6 months. These robots reduce human risk in hazardous areas and provide consistent data collection that manual labor cannot match.

Conclusion

The shift to Physical AI in 2025 represents more than just a hardware upgrade; it is a fundamental change in how machines interact with our world. By moving from rigid programming to experience-based learning, robots like the X30, Lynx M20, and DEEP Robotics Lite 3 have become viable, efficient assets for industry and education alike. Whether you are automating a refinery or teaching the next generation of AI engineers, the era of the intelligent, adaptable quadruped has arrived.