Autonomous Industrial Inspection Solutions

Deploy an autonomous quadruped robot engineered for safe, precise inspections across all industrial sites—from manufacturing floors and chemical plants to pipelines, tunnels, and confined spaces—streamlining asset monitoring, condition tracking, predictive maintenance, and compliance reporting.

DEEP Robotics powers missions for companies worldwide.

Power Patrol Inspection

Tunnel Inspection

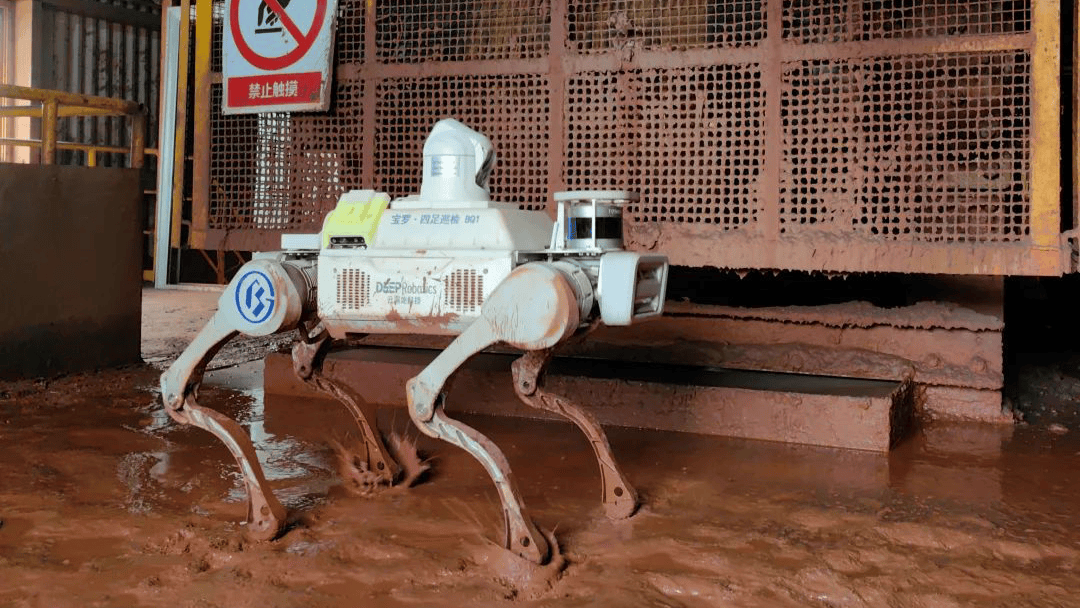

Metal & Mining

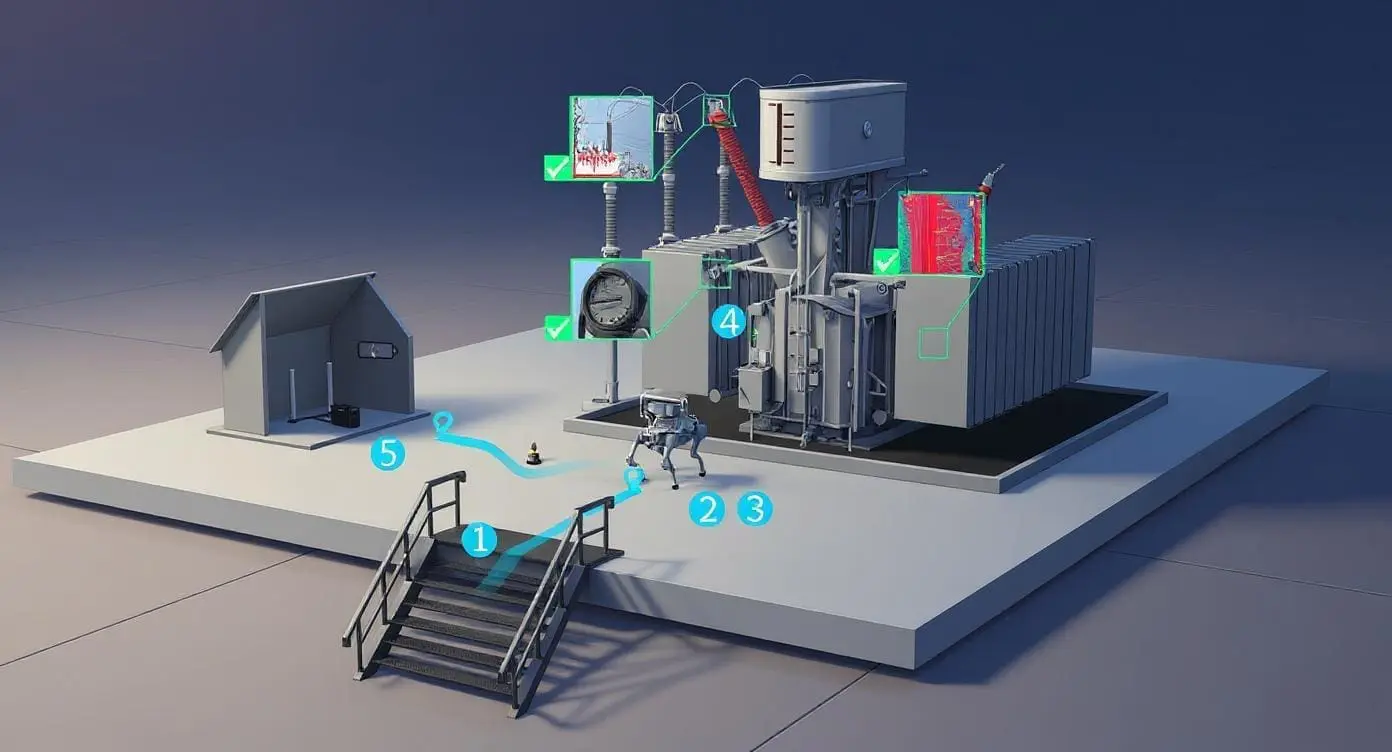

Autonomous Inspection Process

Monitor on‑site conditions in real time, leverage digital, intelligent inspections, and dramatically boost overall inspection efficiency.

01

Identify inspection targets, assess site conditions, and map out navigation routes.

02

Deploy on‑site, configure sensors, and verify mission parameters.

03

Conduct real‑time inspections following pre‑programmed navigation paths.

04

Complete the survey, process data, and generate comprehensive reports.

05

Automatically return for battery recharge and prepare the next inspection cycle.

All-weather, all-terrain inspection capability

Built for extreme environments, our IP66-rated quadruped robot enables continuous 24-hour autonomous inspections, rain or shine. Designed to navigate rugged terrain, climb stairs, and overcome obstacles, it’s ideal for reliable pipeline, substation, and industrial asset inspections.

Reduce Risk, Boost Efficiency with Autonomous Inspection

Our autonomous quadruped inspection robot performs continuous, fully autonomous site inspections—even in severe weather conditions like heavy rain, snow, or high winds. This approach protects human operators by keeping them out of hazardous areas (e.g. confined spaces, chemical plant zones, high-voltage substations), while also eliminating repetitive manual inspection tasks. By automating inspection routines, we streamline survey workflows, accelerate inspection cycles, and boost operational efficiency across pipeline systems, power infrastructure, tunnels, and industrial plants. The result: reduced downtime, lower inspection costs, and more consistent, high-fidelity inspection data to drive predictive maintenance and asset performance.

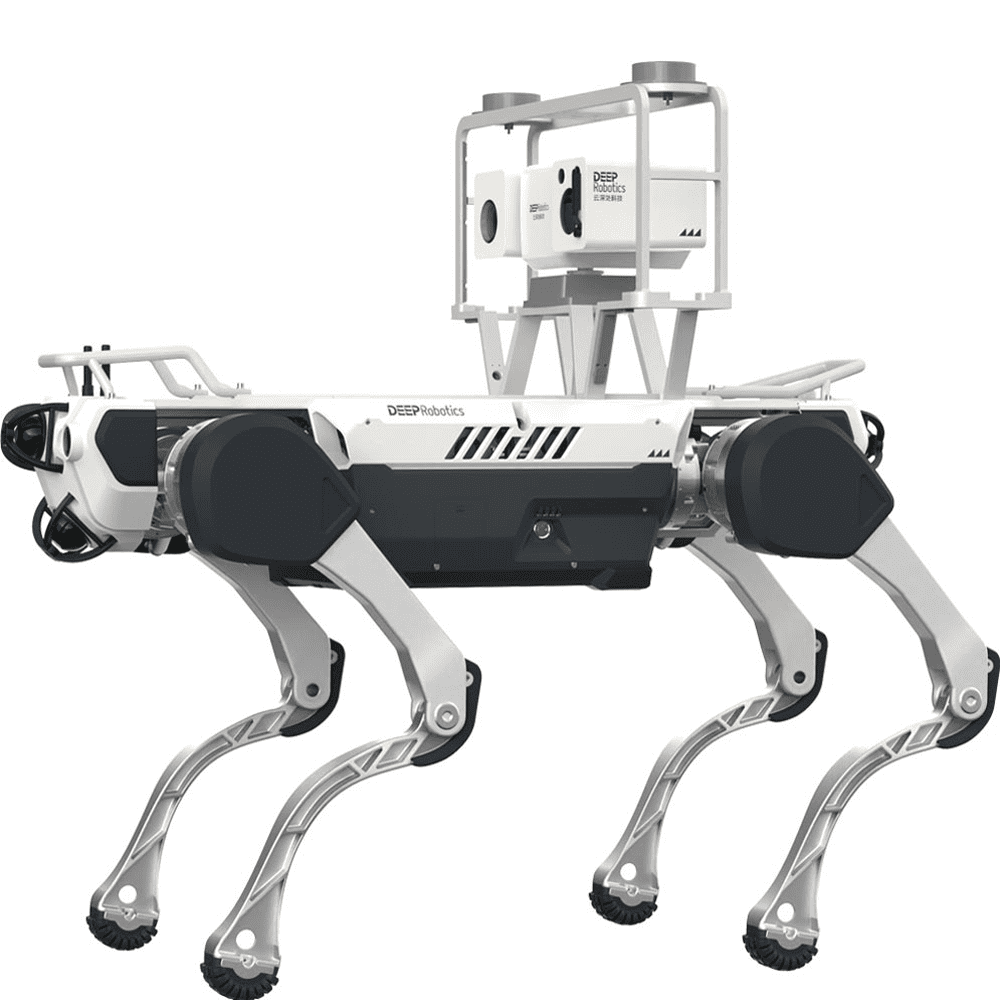

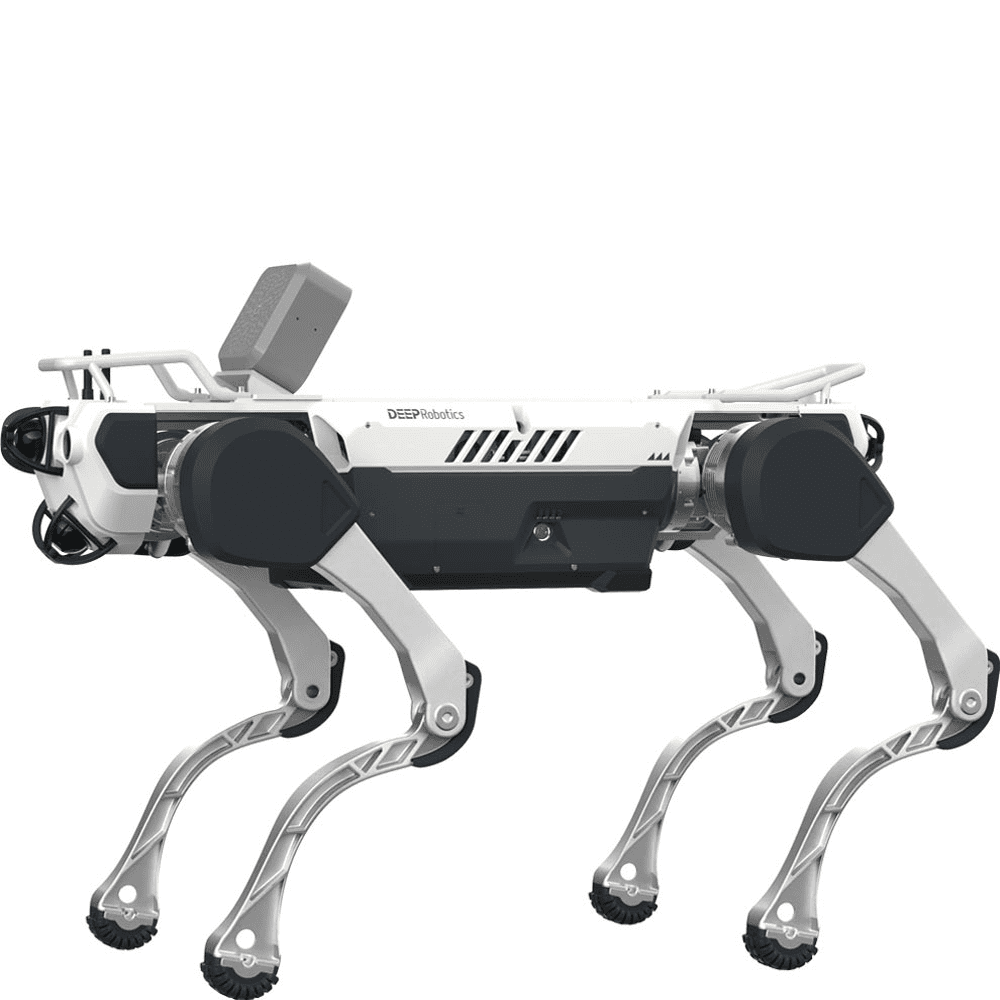

X30 Intelligent Inspection Add-ons

Leverage modular AI‑driven sensors and analytics to capture real‑time site data, streamline digital inspections, and significantly boost inspection accuracy and efficiency.

Bi-spectrum Camera

Equipped with infrared, visible light image transmission, intelligent recognition, defect alarm analysis and other functions, it supports automatic focusing and SDK secondary development.

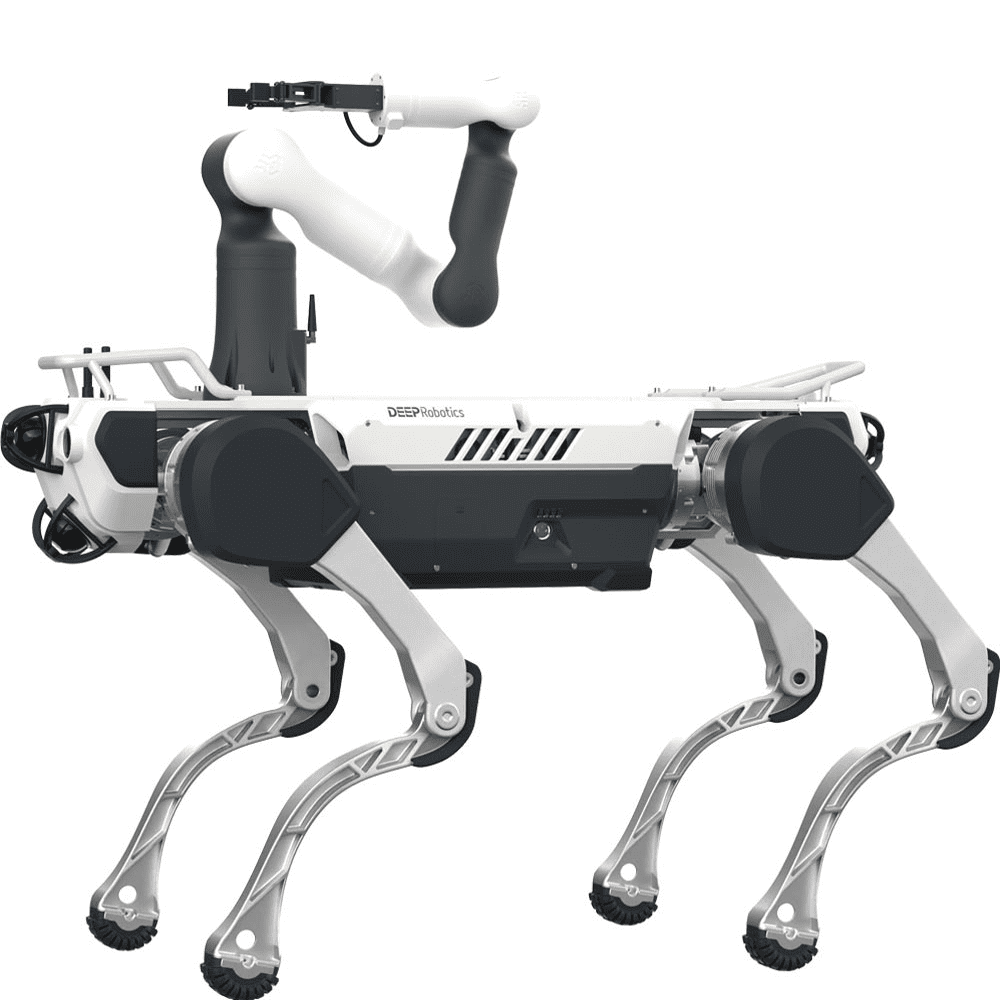

Agile Robotic Arm

It can be equipped with end loads such as a camera and gripper to achieve remote grabbing, switching doors, picking up items, and other operations.

Acoustic Imager

Achieve precise sound source positioning, and more accurately distinguish between corona, along the surface, floating and other types of partial discharge types to quickly troubleshoot problems.

Smart Controller

The navigation host motherboard simultaneously handles business-related program processing, primarily providing functions such as map construction and location navigation.

FAQs – Industrial Inspection Robots

DEEP Robotics industrial inspection robots are advanced quadruped robots such as the X30 and Lynx M20, designed to perform autonomous or semi-autonomous inspections in factories, power plants, oil & gas facilities, utilities, and mining sites. Equipped with cameras, LiDAR, and thermal sensors, these robots navigate complex environments to monitor equipment conditions, detect defects, and improve workplace safety.

The DEEP Robotics X30 and Lynx M20 quadruped robots are versatile platforms for industrial inspections, including:

-

Visual inspections of pipelines, machinery, tanks, and vessels for cracks, leaks, or corrosion

-

Thermal and infrared inspections to detect overheating, insulation problems, or hot spots

-

Structural inspections in tunnels, roofs, or confined spaces

-

Gas detection and chemical sensing in hazardous industrial zones

-

Mapping and 3D scanning for digital twin creation and progress monitoring

Key benefits of deploying DEEP Robotics inspection robots include:

-

Improved safety: robots enter hazardous areas instead of human workers

-

Higher consistency: automated inspections reduce variability and errors

-

Lower downtime: early fault detection prevents costly shutdowns

-

Access to hard-to-reach areas: X30 and Lynx M20 can climb, step, and move through narrow or uneven terrains

-

Smarter data integration: robots provide high-resolution sensor data compatible with predictive maintenance and digital twin platforms

The X30 and Lynx M20 are engineered for demanding inspection tasks with:

-

Terrain adaptability: quadruped locomotion handles rugged, slippery, or confined environments

-

Sensor integration: multiple payloads such as LiDAR, thermal cameras, and visual sensors

-

Autonomous navigation: advanced SLAM, obstacle avoidance, and remote operation modes

-

Durability: industrial-grade IP protection against dust, moisture, and extreme conditions

-

Software compatibility: seamless integration with industrial asset management systems

By capturing consistent, high-resolution data, DEEP Robotics X30 and Lynx M20 quadruped robots identify early warning signs of equipment degradation. Monitoring corrosion, thermal anomalies, or vibration patterns helps companies plan maintenance before failures occur—extending asset life and reducing unexpected downtime.

DEEP Robotics quadruped robots are widely adopted in:

-

Power generation & utilities (substations, power lines, transformers)

-

Oil & gas and petrochemical facilities

-

Chemical and heavy manufacturing plants

-

Mining and metallurgy industries

-

Civil engineering, infrastructure, and tunnel inspections

-

Smart factories and large-scale industrial automation

The X30 and Lynx M20 reduce inspection costs by minimizing labor hours, preventing downtime, and improving safety. While upfront investment includes hardware, sensors, and training, companies see fast ROI through reduced accidents, fewer equipment failures, and improved efficiency.

Yes. DEEP Robotics quadruped robots are built with redundant systems, stable mobility, and compliance with ISO and OSHA safety standards. Emergency stop features, ruggedized design, and reliable sensors ensure safe operation even in harsh industrial conditions.

Absolutely. Both the X30 and Lynx M20 quadruped robots are engineered with high IP ratings, dustproof and waterproof protection, thermal resistance, and optional explosion-proof sensors—making them ideal for hazardous inspection environments.

These robots use integrated cameras, LiDAR, thermal imagers, and gas detectors. Data is transmitted in real time or stored for later analysis. AI-driven software processes inspection data for anomaly detection, mapping, and integration into predictive maintenance systems and digital twins.

Unlike drones, quadruped robots like the X30 and Lynx M20 operate on the ground, making them suitable for indoor environments, tunnels, and confined spaces. They carry heavier sensors, provide more stable imaging, and avoid regulatory airspace restrictions, while drones are better for tall structures and aerial surveys.

Yes. The X30 and Lynx M20 can be customized with sensor payloads (visual, thermal, LiDAR, gas detection), software modifications, and integrations with SCADA and facility management systems. DEEP Robotics also provides APIs and SDKs for tailored industrial solutions.

They address challenges such as:

-

Navigating tight or hazardous spaces

-

Maintaining inspection schedules despite environmental obstacles

-

Managing large amounts of inspection data efficiently

-

Operating reliably in dust, humidity, or extreme temperatures

-

Complying with strict safety and regulatory standards

Consider:

-

Do you have high-risk or costly inspection areas?

-

How frequent are inspections and compliance requirements?

-

Is your team prepared to integrate robotic inspection data into workflows?

-

Does your environment demand rugged, autonomous mobility like that of the X30 or Lynx M20?

The DEEP Robotics X30 offers autonomous mobility and endurance for large-scale inspection tasks, while the Lynx M20 specializes in confined and hazardous environments. Together, they represent the cutting edge of quadruped robotics for industrial inspection—combining safety, durability, precision, and seamless integration with modern industrial systems.