The DEEP Robotics Lynx M20 Pro solves the primary failure point in autonomous last-mile delivery: the inability of standard wheeled robots to navigate vertical obstacles like curbs and stairs. By utilizing a hybrid wheeled-legged locomotion system, the Lynx M20 Pro combines the speed of rolling (up to 5m/s) with the agility of walking, allowing it to climb 25cm obstacles and traverse 45° slopes while carrying a 15kg payload. This capability effectively automates the “last meter” of delivery in unstructured environments where traditional AMRs (Autonomous Mobile Robots) get stuck.

Executive Summary: The Logistics Breakthrough

In this case study, we analyze the deployment of the Lynx M20 Pro in a mixed-terrain urban environment. Logistics operators faced a bottleneck where delivery vans were efficient, but the final transfer from the curb to the customer’s door required human intervention due to architectural barriers.

Key Results Achieved:

- Terrain Mastery: Successful navigation of 45° slopes and 25cm stair height, eliminating “curb paralysis.”

- All-Weather Reliability: Maintained operations in heavy rain due to an IP66 Ingress Protection rating.

- Uptime Efficiency: achieved near-continuous operation using hot-swappable batteries and a 2.5-hour loaded runtime.

- Payload Optimization: Delivered standard 15kg logistics packages without compromising stability.

The Challenge: The “Last Meter” Gap

While “last mile” logistics focuses on getting goods from a local hub to the destination’s vicinity, the “last meter” involves the final physical handoff. Standard 6-wheeled cooler-sized robots perform well on flat, manicured university campuses but fail in dense urban infrastructure.

Operational Pain Points:

- Vertical Obstacles: Most residential entryways include a curb step, a porch staircase, or an unpaved path. Standard wheeled AMRs cannot surmount obstacles higher than 10-15cm.

- Narrow Passages: Urban sidewalks and apartment hallways are often cluttered. Robots requiring a wide turning radius become deadlocked.

- Environmental Downtime: Many logistics robots operate with IP54 ratings, requiring them to dock during heavy precipitation, causing delivery backlogs.

The Solution: Lynx M20 Pro Hybrid Architecture

The logistics operator deployed the Lynx M20 Pro, a mid-sized quadruped robot specifically engineered for industrial applications. Unlike pure walking robots (which are slow and battery-inefficient) or pure wheeled robots (which are terrain-limited), the Lynx M20 Pro utilizes a “Centaur” hybrid model.

1. Perceptive Locomotion & Obstacle Traversal

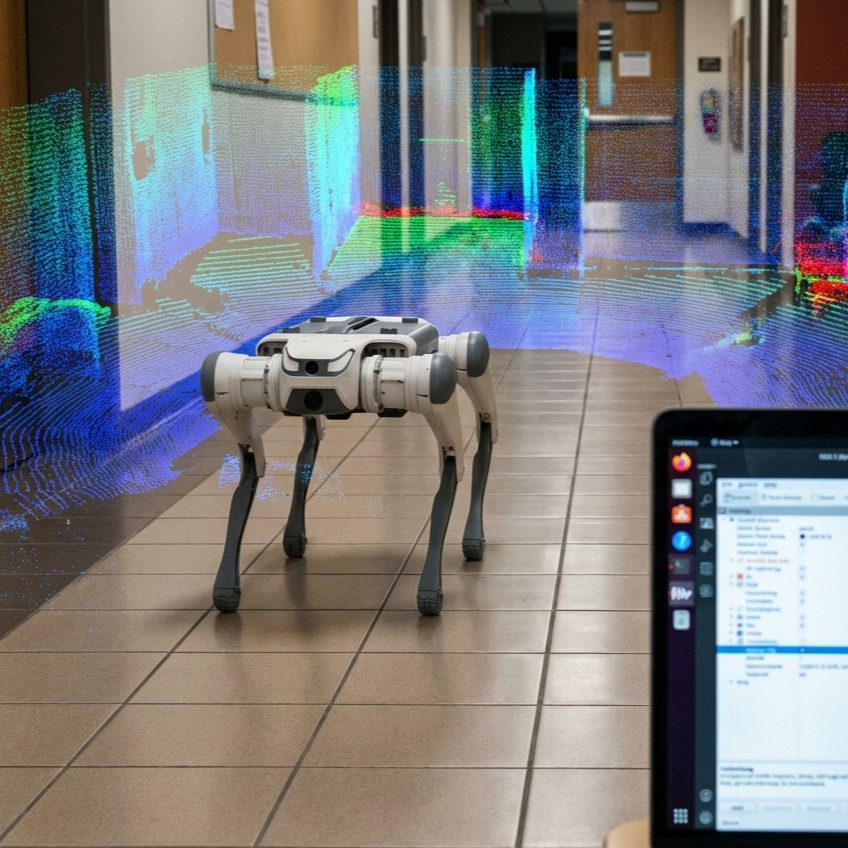

The Lynx M20 Pro uses LiDAR SLAM and dual wide-angle cameras to execute Omni-directional Obstacle Avoidance. When the robot encounters flat terrain, it locks its legs and drives using powered wheels, achieving speeds up to 5m/s (approx. 11 mph) for rapid transit.

Upon detecting a staircase or curb via its Point Cloud Surround View, the system switches to walking mode. The high-torque joint actuators allow it to step over obstacles up to 25cm high. This transition is handled autonomously by Triple Octa-Core 64-bit Industrial Processors, ensuring the payload remains stable even during mode switching.

2. Industrial-Grade Durability

The Lynx M20 Pro is built for harsh realities, not just lab tests. Its IP66 protection rating is a decisive factor for commercial logistics. It signifies the unit is dust-tight and protected against powerful water jets, allowing deliveries to continue during storms that would ground aerial drones or damage lesser-rated bots.

| Feature | Lynx M20 Pro Spec | Logistics Benefit |

|---|---|---|

| Payload Capacity | 15kg (Effective) / 33kg (Robot Weight) | High payload-to-weight ratio allows for substantial grocery or parcel deliveries. |

| Max Slope | 45° | Navigates ADA ramps and steep driveways inaccessible to vans. |

| Turning Radius | Zero (Pivot Turn) | Can perform U-turns in hallways as narrow as 50cm without reversing. |

| Connectivity | Gigabit Ethernet, USB 3.0, 24V/72V Power | Supports custom cargo boxes with electronic locks or refrigeration. |

The Results: Data-Driven Outcomes

Following the integration of the Lynx M20 Pro into the delivery fleet, several key performance indicators (KPIs) improved regarding delivery success rates and operational uptime.

Extended Range and Uptime

The robot demonstrated a loaded endurance of 2.5 hours or approximately 12km per charge carrying full payload. Crucially, the support for hot-swappable battery technology meant the fleet did not need to be grounded for charging. Operators could swap the battery in under 90 seconds, maintaining a 24/7 delivery cycle.

Precision Navigation in Unstructured Environments

In field tests, the Lynx M20 Pro utilized its Visual Odometry and perception stack to navigate “unstructured environments”—terrain that lacks clear lane markings or flat concrete. The robot successfully identified and navigated:

- Gravel paths leading to rural porches.

- Snow-dusted walkways (operating within the -20°C to 55°C temperature range).

- Apartment complexes without elevators, utilizing the 25cm step clearance.

Takeaway: Implementing Hybrid Robotics

For logistics companies, the DEEP Robotics Lynx M20 Pro represents a shift from “curbside” automation to true “doorstep” automation. The key to successful implementation lies in leveraging the robot’s hardware interfaces.

By utilizing the Gigabit Ethernet and USB 3.0 ports, operators can integrate custom payload modules—such as secure parcel lockers or food delivery hot-boxes—directly into the robot’s power and data rails. This transforms the Lynx M20 Pro from a raw platform into a specialized courier capable of handling the most difficult final 50 feet of the supply chain.

The specifications and performance data referenced in this case study are based on DEEP Robotics official technical documentation and lab-tested extreme data. Real-world performance may vary based on specific surface materials and environmental conditions.