- Core Innovation: Hybrid locomotion combines the low Cost of Transport (CoT) of wheels with the obstacle-crossing capability of legs.

- Key Spec: The Lynx M20 features an IP66 rating and can navigate 45° slopes, bridging the gap between delicate research robots and heavy industrial tools.

- Control Logic: It utilizes Model Predictive Control (MPC) and Reinforcement Learning (RL) to transition seamlessly between rolling and stepping.

- Market Position: A mid-sized industrial platform that competes with Boston Dynamics Spot and Unitree on price-to-performance.

Wheel-leg locomotion is a hybrid robotic movement strategy that utilizes active suspension to alternate between rolling on flat surfaces and stepping over obstacles. The Deep Robotics Lynx M20 exemplifies this technology, solving the “efficiency vs. agility” trade-off that has historically plagued mobile robotics. By unlocking its wheels to skate like a car or locking them to walk like a quadruped, the Lynx M20 achieves high-speed efficiency on concrete while maintaining the ability to climb stairs, traverse rubble, and navigate narrow 50cm trenches.

Definition: Active Suspension Locomotion

A robotic control method where the joints (legs) actively manage the position and force of the contact points (wheels). Unlike a passive car suspension that reacts to bumps, the Lynx M20 anticipates terrain, lifting wheels over obstacles while maintaining forward momentum.

The “Why”: Solving the Efficiency Paradox

For decades, roboticists faced a binary choice: use wheels for speed or legs for terrain. The Lynx M20 renders this choice obsolete through convergent kinematics. The primary driver for this shift is the Cost of Transport (CoT), a metric measuring the energy required to move a specific mass over a specific distance.

Traditional quadrupeds (like Spot) have a high CoT on flat ground because they must constantly lift and accelerate their legs, fighting gravity with every step. Wheeled robots have a low CoT but fail at the “last meter”—the curb, the stairwell, or the debris pile. The Lynx M20 minimizes energy consumption by rolling 90% of the time and only expending high energy (stepping) when the terrain demands it.

Core Advantages of the Hybrid Approach

- Simultaneous Motion: The “Driving-Stepping Controller” decouples forward velocity. The robot can roll forward with three wheels while the fourth lifts to clear an obstacle.

- Payload Stability: Because the legs act as active dampeners, the main chassis (and sensitive LiDAR/camera payloads) remains level even when traversing rough gravel or 45° inclines.

- Extended Range: Rolling reduces battery drain, allowing the Lynx M20 to achieve up to 3 hours of unloaded endurance or a 15km range.

Deep Dive: Lynx M20 Technical Capabilities

The Lynx M20 is not just a concept; it is a ruggedized industrial tool designed for unstructured environments. Based on official technical specifications, the robot is built to withstand environmental stressors that would disable consumer-grade electronics.

| Feature | Specification | Operational Benefit |

|---|---|---|

| Dimensions | 0.82m × 0.43m × 0.57m | Compact enough for human corridors. |

| Weight / Payload | 33kg / 15kg | High payload-to-weight ratio for sensors. |

| Protection Rating | IP66 | Dust-tight and resistant to powerful water jets. |

| Maximum Speed | 5 m/s (Lab) / 2-3 m/s (Field) | Significantly faster than walking-only robots. |

| Endurance | 3 Hours / 15km | Sufficient for long-range perimeter security. |

The “Front-Elbow / Rear-Knee” Configuration

One of the most distinct features of the Lynx M20 is its kinematic flexibility. It can adopt a “Front-Elbow / Rear-Knee” stance, where the front legs articulate forward and the rear legs articulate backward. This reduces the vertical profile and length, allowing the robot to perform omnidirectional obstacle avoidance and squeeze through passages as narrow as 50cm. This is critical for substations and disaster zones where debris narrows the path.

Control Strategies: MPC and Reinforcement Learning

Hardware is only half the equation. The “Brain” of the Lynx M20 relies on advanced algorithmic hierarchies to manage the complex transitions between wheel and leg modes.

1. Model Predictive Control (MPC)

Used primarily during high-speed rolling, MPC looks milliseconds into the future. It predicts the robot’s state and adjusts wheel torque and leg height to maintain the centroidal dynamics. This prevents the robot from tipping over when cornering at 3 m/s or braking suddenly on a slope.

2. Reinforcement Learning (RL) & Blind Locomotion

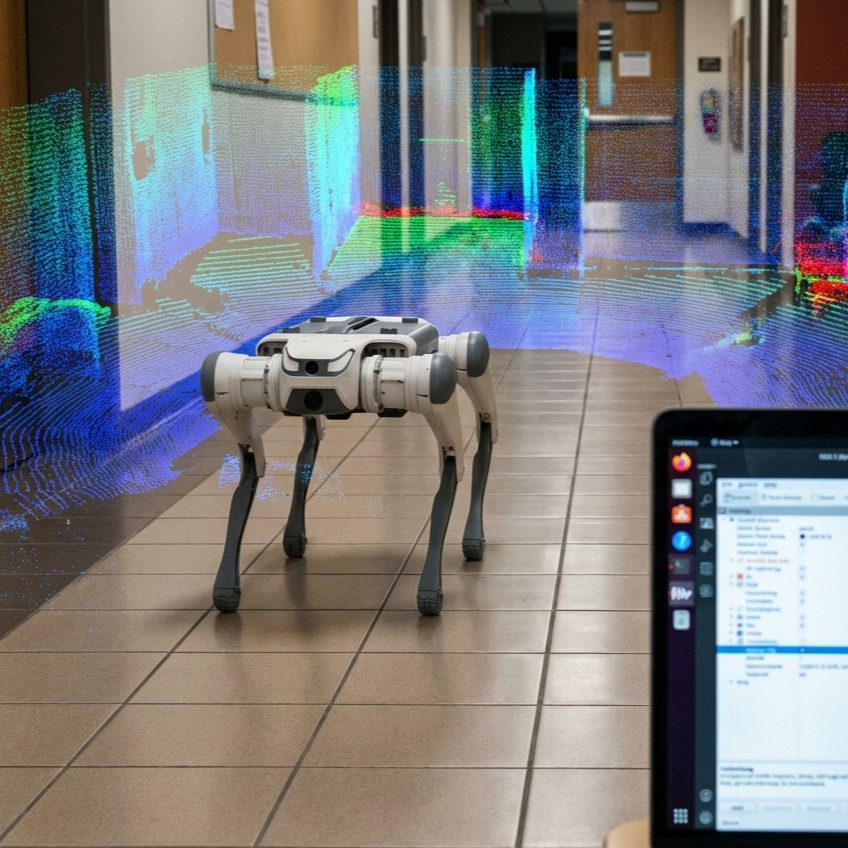

In environments where vision fails—such as smoke-filled rescue sites or heavy fog—LiDAR and cameras become unreliable. The Lynx M20 utilizes RL policies trained in simulation to perform “blind locomotion.” It relies on proprioception (internal sensing of joint angles and motor currents) to “feel” the terrain, recovering from slips and stumbling over unknown debris without needing a visual map.

Industrial Applications

The Lynx M20 is engineered for sectors where human access is dangerous or inefficient. The combination of triple octa-core processors and multi-sensor fusion (LiDAR + Dual Wide-Angle Cameras) enables autonomy in the following scenarios:

- Power Grid Inspection: The robot traverses gravel yards and climbs concrete pads to inspect transformers. The IP66 rating ensures operation during rainstorms when electrical faults are most common.

- Emergency Rescue: Capable of carrying 15kg of medical supplies or communication relays over rubble that would stop a wheeled rover.

- Logistics Delivery: Solving the “last 100 feet” delivery challenge by rolling down the street and stepping up to the porch.

Frequently Asked Questions (FAQ)

What is the main advantage of a wheel-legged robot over a quadruped?

The primary advantage is energy efficiency and speed. On flat surfaces, the Lynx M20 rolls, which requires significantly less battery power than the constant stepping motion of a quadruped. However, unlike a purely wheeled robot, it retains the ability to lock its wheels and step over obstacles, offering the best of both worlds.

Can the Lynx M20 operate in rain or dust?

Yes. The Lynx M20 possesses an IP66 protection rating. This means it is completely dust-tight and protected against powerful water jets from any direction. It also operates in temperatures ranging from -20°C to 55°C, making it suitable for extreme climates.

How does the Lynx M20 handle continuous operation?

The robot features hot-swappable battery technology. Operators can replace a depleted battery with a fresh one without powering down the robot’s onboard computers or sensors. This allows for near-continuous 24/7 operation in critical security or inspection shifts.

Conclusion

The Deep Robotics Lynx M20 represents a maturing of mobile robotics. By moving beyond the “wheel vs. leg” debate and adopting a hybrid architecture, it delivers the versatility required for real-world industrial applications. Whether navigating a cluttered factory floor or inspecting a remote substation in the rain, the Lynx M20’s active suspension and intelligent control systems define the new standard for autonomous terrain adaptability.